The welding industry faces ongoing changes in material requirements, technology advancements, and shifting demand patterns. This evolution raises important questions about whether regional supply chains can adequately meet the needs of welding material users. As manufacturers and fabricators adapt to new challenges, understanding the capabilities and limitations of localized supply networks becomes increasingly relevant.

Current State of Welding Material Supply Chains

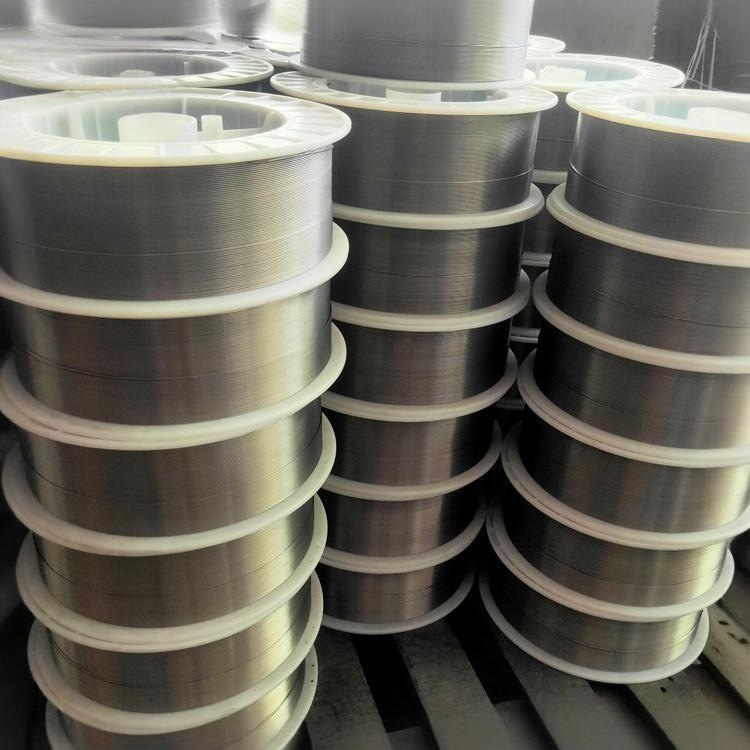

Regional supply chains for welding materials have developed significantly in recent years. Many areas now host multiple suppliers offering various consumables, from basic electrodes to specialized filler metals. This development has reduced dependence on distant sources for some users while creating new considerations for others.

The concentration of suppliers within specific regions allows for shorter lead times compared to international shipments. Local distributors often maintain inventory levels that can respond quickly to urgent requests, which proves valuable for time-sensitive projects. However, product variety and technical specialization sometimes remain more limited than global supply options.

Advantages of Regional Supply Networks

Several benefits emerge when welding material users engage with regional suppliers. Reduced transportation distances typically result in lower logistics costs and decreased vulnerability to international shipping disruptions. The proximity also facilitates stronger relationships between buyers and sellers, often leading to better technical support and more customized service.

Regional suppliers frequently develop deeper understanding of local industry requirements. This knowledge enables them to stock appropriate material grades and recommend suitable alternatives when specific products become temporarily unavailable. The shorter supply lines also allow for more flexible order quantities, benefiting smaller operations that don't require bulk purchases.

Challenges in Meeting Diverse Requirements

Despite these advantages, regional supply chains face obstacles in fully addressing all user needs. Highly specialized welding materials, particularly those used in niche applications or extreme conditions, may not be economically viable for local distributors to stock regularly. Users requiring these products often still rely on national or international suppliers.

Technical expertise availability varies significantly across regions. While some areas boast numerous qualified welding engineers and metallurgists, others may lack sufficient local knowledge to support advanced applications. This disparity can limit the ability of regional suppliers to provide comprehensive solutions for complex welding challenges.

Adapting to Changing Industry Demands

The welding industry continues to evolve with new material formulations and application methods. Regional suppliers must demonstrate adaptability to remain relevant. Some have invested in expanded inventory management systems, while others have formed alliances to broaden their collective product offerings without maintaining excessive stock.

Digital tools have enabled better coordination between regional suppliers and their customers. Online ordering platforms, inventory visibility systems, and technical support portals help bridge gaps that previously required physical proximity. These developments enhance the value proposition of localized supply chains.

Future Outlook

The capacity of regional supply chains to support welding material users will likely depend on several factors. Continued investment in inventory diversity, technical training, and digital infrastructure appears necessary to meet growing expectations. Partnerships between regional suppliers may offer pathways to combine resources while maintaining local presence and responsiveness.

As welding technologies advance and material requirements become more specific, the balance between regional availability and specialized needs will require ongoing attention. Users with standard requirements will probably find regional supply chains increasingly capable, while those with highly specialized needs may continue supplementing with broader sourcing options.

Conclusion

Regional supply chains have demonstrated their ability to support many welding material users effectively, particularly for common applications and standard materials. While challenges remain in addressing highly specialized requirements, ongoing improvements in inventory management, technical support, and digital connectivity continue to enhance regional capabilities. For most welding operations, a balanced approach combining regional suppliers with selective broader sourcing appears to offer practical solutions to evolving material needs.