Product Forms

Your Current Location: Home >> Product Forms >> Coil/Strip >> Hastelloy

HASTELLOY X(UNSN06002) COIL/STRIP

Nickel-Chromium-Iron-Molybdenum Alloy for High-Temperature & Oxidation Resistance

HASTELLOY X strip is used for high-temperature components requiring oxidation resistance and good fabricability, including furnace internals, baffles, and honeycomb structures. Strip is commonly supplied in coils for slitting, stamping, and forming.

As a professional Chinese nickel-based alloy manufacturer, we supply HASTELLOY X strip with stable chemistry, consistent mechanical properties, and flexible dimensional customization for global industrial users.

Typical supply range (custom sizes and tolerances available upon request):

Item | Range / Options | Notes |

Thickness | 0.05 – 3.0 mm | Define tolerance if critical (slitting applications). |

Width | 10 – 600 mm | Slitting available; define edge condition. |

Coil ID | 300 / 400 / 508 mm | Other IDs available by agreement. |

Coil OD | Up to 1500 mm | Depends on thickness and coil weight. |

Edge | Slit / Rounded | Deburring and edge conditioning available. |

Surface finish | 2B / BA / Polished | PVC protective film optional. |

Delivery condition | Solution annealed (standard) | Bright annealed option for thin strip. |

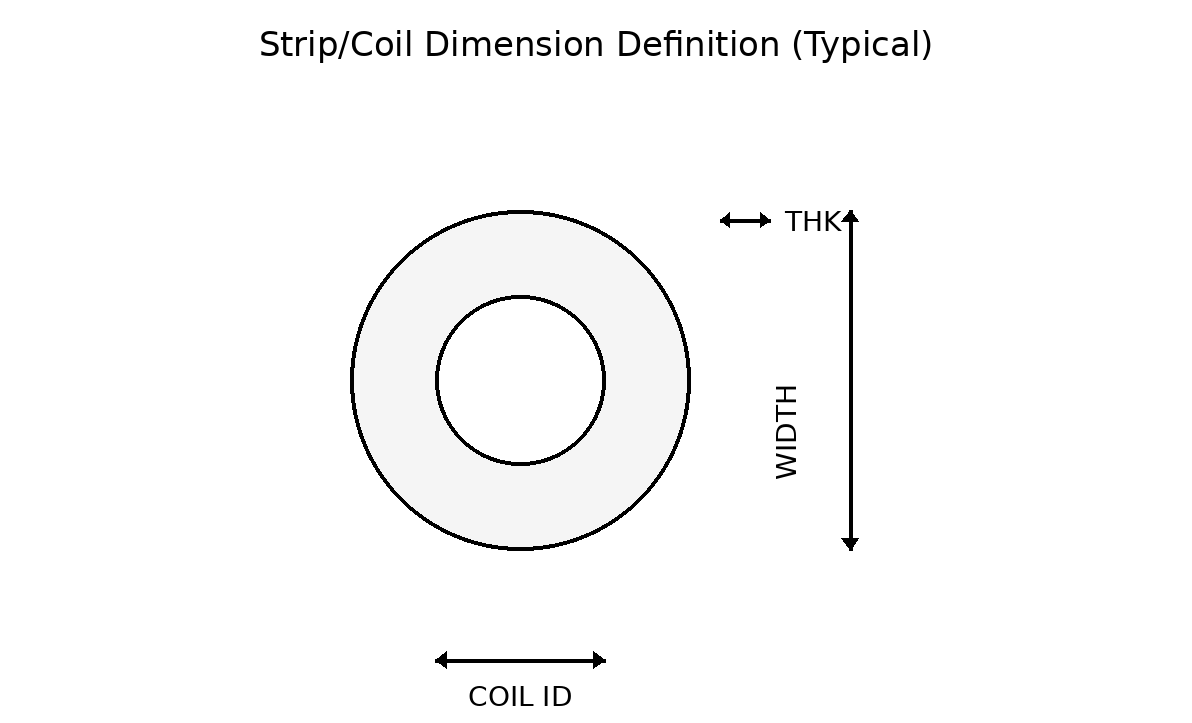

Dimension definition: THK × WIDTH × COIL.

• Excellent high-temperature strength and oxidation resistance

• Good fabricability and weldability for complex fabricated structures

• Good resistance to carburizing and nitriding furnace atmospheres

• Resistant to stress-corrosion cracking in certain petrochemical environments

• Suitable for oxidizing, reducing, and neutral atmospheres in furnace service

Element | Ni | Cr | Mo | Fe | W | Mn | Si | C |

HASTELLOY X | Balance | 20.5–23.0 | 8.0–10.0 | 17.0–20.0 | 0.2–1.0 | ≤1.0 | ≤1.0 | 0.05–0.15 |

Nominal/typical chemistry is shown. Typical additions include Co (0.5–2.5 wt.%) and minor elements such as B (≤0.008) to support high-temperature performance.

Property | Value |

Tensile Strength (Rm) | ≈ 783 MPa |

Yield Strength (Rp0.2) | ≈ 376 MPa |

Elongation | ≈ 46 % |

Hardness | ≈ 86–92 HRB |

Mechanical properties may vary slightly with product form and heat treatment condition.

Standard System | Specification |

ASTM / ASME | ASTM B435 / ASME SB-435 |

EN | EN 10204 |

UNS | N06002 |

DIN | 2.4665 |

JIS | NW6002 |

Item | Range |

Thickness | 0.05 – 3.0 mm |

Width | 10 – 600 mm |

Coil ID | 300 / 400 / 508 mm |

Surface Finish | 2B / BA / Polished |

Edge | Slit / Rounded |

Custom sizes, tight tolerances, and cut-to-length service are available upon request.

• Solution Annealed

• Bright Annealed / Pickled (where applicable)

• Furnace baffles, trays, fixtures, and internal structural parts

• Catalyst support grids and high-temperature screens

• Honeycomb structures and formed combustion components

• Fabricated parts for oxidizing/reducing/neutral furnace atmospheres

HASTELLOY X can be fabricated and welded using standard nickel-alloy practices.

Common welding methods include:

• GTAW (TIG)

• GMAW (MIG)

• SMAW

Matching filler metals such as ERNiCrMo-2 are typically recommended.

• EN 10204 3.1 Material Test Certificate

• Chemical composition analysis

• Mechanical testing (tensile, hardness)

• PMI / XRF testing available

• Dimensional inspection

• Third-party inspection on request (BV, SGS, TUV, DNV)

• PVC protective film on surface (where applicable)

• Wooden pallets or export-grade crates

• Seaworthy packaging for long-distance shipment

• Global delivery by sea, air, or multimodal transport

• Professional nickel-based alloy manufacturer in China

• Stable raw material sourcing and melting control

• Wide stock and fast production cycle

• Competitive pricing for global projects

• Experience with international EPC, OEM, and distributors

For quotation or technical consultation, please provide:

• Required grade (HASTELLOY X)

• Thickness × Width × Coil ID/Weight

• Quantity

• Surface finish / delivery condition

• Application environment

Our technical team will respond with datasheets, pricing, and delivery schedule promptly.