Product Forms

Your Current Location: Home >> Product Forms >> Tube/Pipe >> Hastelloy

HASTELLOY X(UNSN06002) PIPE / TUBE

Nickel-Chromium-Iron-Molybdenum Alloy for High-Temperature & Oxidation Resistance

HASTELLOY X pipe/tube is selected for high-temperature oxidation service and furnace process lines where strength, fabricability, and thermal stability are required. It is widely used for tubing in pyrolysis operations and other high-temperature process equipment.

As a professional Chinese nickel-based alloy manufacturer, we supply HASTELLOY X pipe and tube with stable chemistry, consistent mechanical properties, and flexible dimensional customization for global industrial users.

Typical supply range (custom sizes and tolerances available upon request):

Item | Range / Options | Notes |

Outside Diameter (OD) | 6 – 600 mm | Tube or pipe per project; NPS/DN on request. |

Wall Thickness (WT) | 0.5 – 30 mm | Define tolerance if critical. |

Length | Up to 12000 mm | Random / fixed length available by agreement. |

Type | Seamless / Welded | ASTM B622 (seamless); ASTM B619/B626 (welded) per requirement. |

Surface finish | Pickled / Bright / Polished | ID/OD finish by agreement. |

End | Plain / Beveled | End prep available for welding and assembly. |

Delivery condition | Solution annealed (standard) | Additional NDT/HT per project requirement. |

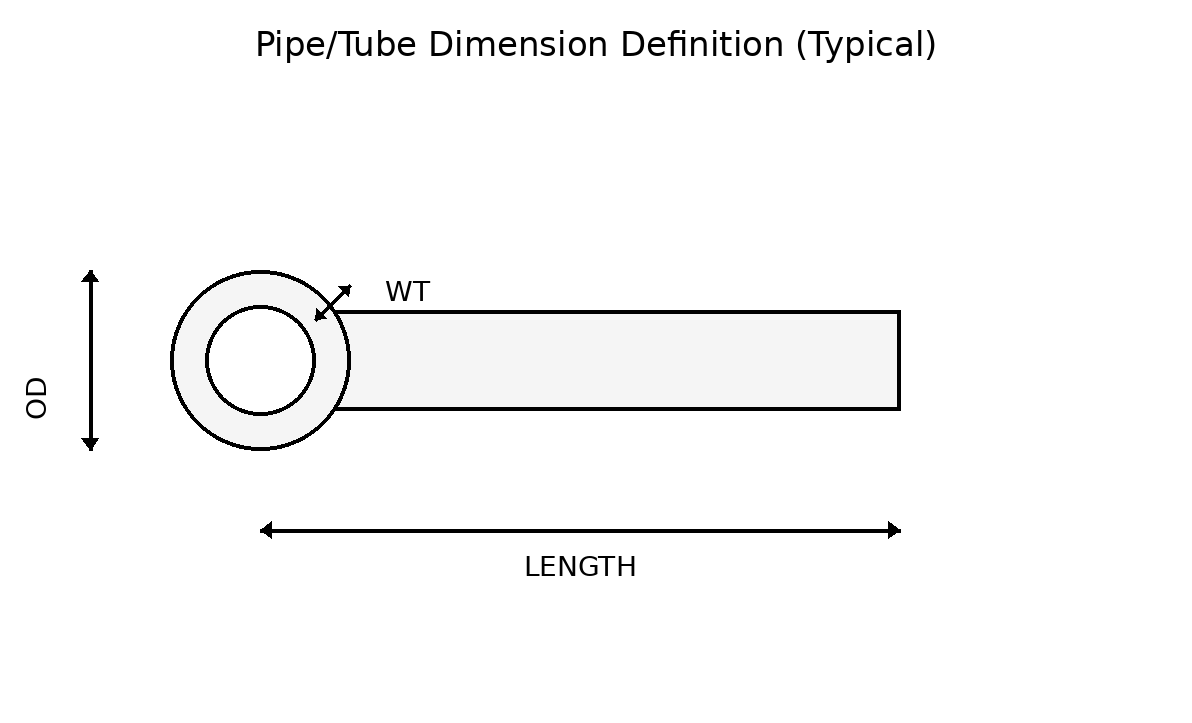

Dimension definition: OD × WT × LENGTH.

• Excellent high-temperature strength and oxidation resistance

• Good fabricability and weldability for complex fabricated structures

• Good resistance to carburizing and nitriding furnace atmospheres

• Resistant to stress-corrosion cracking in certain petrochemical environments

• Suitable for oxidizing, reducing, and neutral atmospheres in furnace service

Element | Ni | Cr | Mo | Fe | W | Mn | Si | C |

HASTELLOY X | Balance | 20.5–23.0 | 8.0–10.0 | 17.0–20.0 | 0.2–1.0 | ≤1.0 | ≤1.0 | 0.05–0.15 |

Nominal/typical chemistry is shown. Typical additions include Co (0.5–2.5 wt.%) and minor elements such as B (≤0.008) to support high-temperature performance.

Property | Value |

Tensile Strength (Rm) | ≈ 760–783 MPa |

Yield Strength (Rp0.2) | ≈ 340–376 MPa |

Elongation | ≈ 45–49 % |

Hardness | ≈ 87–92 HRB |

Mechanical properties may vary slightly with product form and heat treatment condition.

Standard System | Specification |

ASTM / ASME | ASTM B622 / ASME SB-622 (seamless); ASTM B619/B626 (welded) |

EN | EN 10204 |

UNS | N06002 |

DIN | 2.4665 |

JIS | NW6002 |

Item | Range |

OD | 6 – 600 mm |

WT | 0.5 – 30 mm |

Length | up to 12000 mm |

Type | Seamless / Welded |

End | Plain / Beveled |

Custom sizes, tight tolerances, and cut-to-length service are available upon request.

• Solution Annealed

• Bright Annealed / Pickled (where applicable)

• Tubing for pyrolysis operations and flash drier components

• Furnace radiant tubes and high-temperature process lines

• Gas turbine and hot-gas path auxiliary tubing

• Petrochemical furnace pigtails and manifolds (project-defined)

HASTELLOY X can be fabricated and welded using standard nickel-alloy practices.

Common welding methods include:

• GTAW (TIG)

• GMAW (MIG)

• SMAW

Matching filler metals such as ERNiCrMo-2 are typically recommended.

• EN 10204 3.1 Material Test Certificate

• Chemical composition analysis

• Mechanical testing (tensile, hardness)

• PMI / XRF testing available

• Dimensional inspection

• Third-party inspection on request (BV, SGS, TUV, DNV)

• PVC protective film on surface (where applicable)

• Wooden pallets or export-grade crates

• Seaworthy packaging for long-distance shipment

• Global delivery by sea, air, or multimodal transport

• Professional nickel-based alloy manufacturer in China

• Stable raw material sourcing and melting control

• Wide stock and fast production cycle

• Competitive pricing for global projects

• Experience with international EPC, OEM, and distributors

For quotation or technical consultation, please provide:

• Required grade (HASTELLOY X)

• OD × WT × Length

• Quantity

• Surface finish / delivery condition

• Application environment

Our technical team will respond with datasheets, pricing, and delivery schedule promptly.