Alloy Grades

Your Current Location: Home >> Alloy Grades >> Incoloy >> Wire

INCOLOY 825(UNSN08825) WIRE

Nickel-Iron-Chromium-Molybdenum-Copper Alloy for Superior Acid and Chloride Corrosion Resistance

INCOLOY 825 wire is supplied for corrosion-resistant fasteners, springs, woven mesh, and also as welding wire/filler applications where compatibility with C-22 base metal is required. The alloy maintains excellent corrosion resistance in both oxidizing and reducing environments and is suitable for demanding chemical process and pollution-control services.

As a professional Chinese nickel-based alloy manufacturer, we supply INCOLOY 825 in multiple product forms with stable chemistry, consistent mechanical properties, and flexible dimensional customization for global industrial users.

Typical supply range (custom sizes and tolerances available upon request):

Item | Range / Options | Notes |

Diameter | 0.5 – 20 mm | Wire in coils/spools; straight lengths by request (limited sizes). |

Form | Coil / Spool / Straight | Packaging per diameter and customer requirement. |

Surface finish | Bright / Pickled / Descaled | Surface condition per application (forming/welding). |

Packaging | Spools / Coils | Labeling and moisture-proof packing available. |

Tolerance | Per ASTM/EN or as agreed | Define diameter tolerance for precision wire. |

Straightness | As agreed | For straight wire, define straightness and cut length tolerance. |

Delivery condition | Solution annealed (standard) | Annealed & pickled/bright depending on finish. |

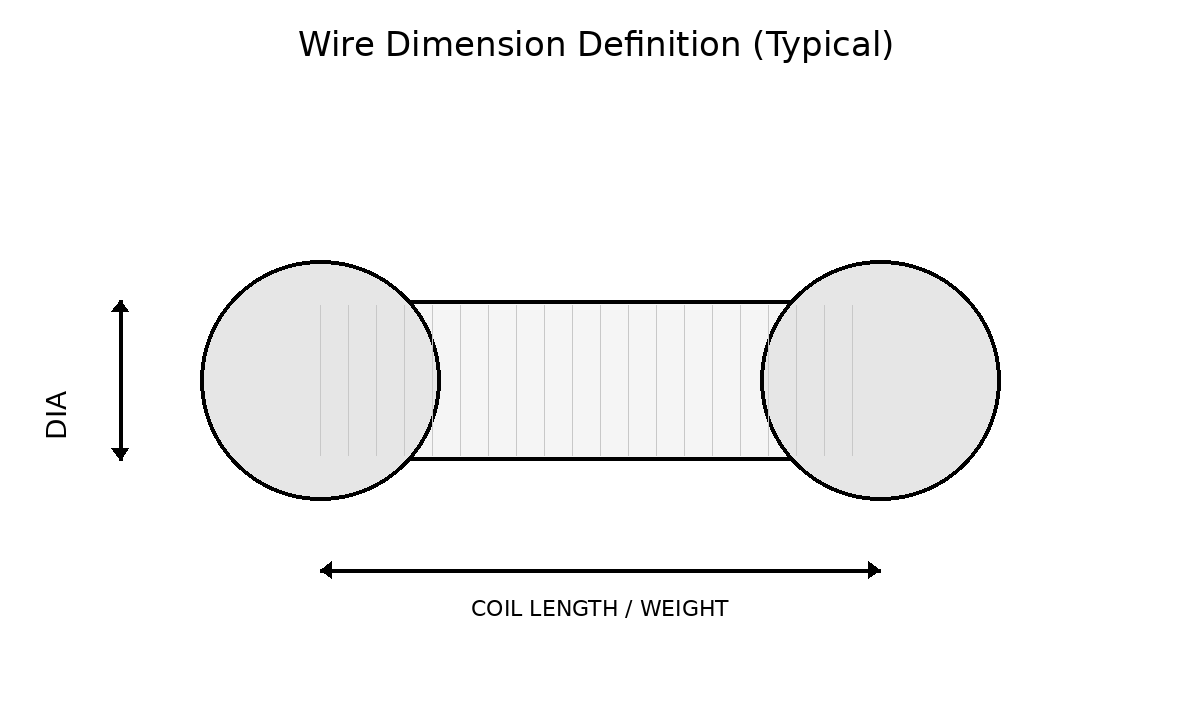

Dimension definition: DIA × COIL/SPOOL.

• Excellent resistance to sulfuric and phosphoric acids across wide concentration ranges

• Strong resistance to chloride stress corrosion cracking and crevice corrosion

• Good resistance to reducing and oxidizing media; performs well in mixed acid systems

• Molybdenum and copper enhance resistance to reducing acids and pitting environments

• Titanium stabilization improves resistance to intergranular corrosion after welding

• Good fabricability and weldability for chemical process equipment

Element | Ni | Cr | Mo | Fe | Cu | Mn | Si | C |

INCOLOY 825 | Balance | 20.0–22.5 | 12.5–14.5 | 2.0–6.0 | 2.5–3.5 | ≤0.50 | ≤0.08 | ≤0.015 |

Extremely low carbon and silicon help maintain corrosion resistance in as-welded structures.

Property | Value |

Tensile Strength (Rm) | ≥ 550 MPa |

Yield Strength (Rp0.2) | ≥ 220 MPa |

Elongation | ≥ 30 % |

Hardness | ≤ 90 HRB |

Mechanical properties may vary slightly with product form and heat treatment condition.

Standard System | Specification |

ASTM / ASME | ASTM B425 / ASME SB-425 |

EN | EN 10204 |

UNS | N06022 |

DIN | 2.4858 |

JIS | NW 6022 |

Item | Range |

Diameter | 0.5 – 20 mm |

Form | Coil / Spool / Straight |

Surface Finish | Bright / Pickled / Descaled |

Packaging | Spools / Coils |

Delivery condition | Solution annealed (standard) |

Custom sizes, tight tolerances, and cut-to-length service are available upon request.

• Solution Annealed

• Annealed & Pickled (where applicable)

• Chemical processing equipment, tanks, columns, heat exchangers and piping

• Sulfuric acid and phosphoric acid production, pickling and acid handling systems

• Oil and gas sour service components, offshore piping and marine hardware

• Pollution-control and FGD scrubbers, ducting and absorber internals

• Heat exchanger and condenser tubing, seawater/brine service (as applicable)

• Nuclear fuel reprocessing and high-corrosion environments

INCOLOY 825 can be fabricated and welded using standard nickel-alloy practices.

Common welding methods include:

• GTAW (TIG)

• GMAW (MIG)

• SMAW

Matching filler metals such as ERNiCrMo-3 are typically recommended.

• EN 10204 3.1 Material Test Certificate

• Chemical composition analysis

• Mechanical testing (tensile, hardness)

• PMI / XRF testing available

• Dimensional inspection

• Third-party inspection on request (BV, SGS, TUV, DNV)

• PVC protective film on surface (where applicable)

• Wooden pallets or export-grade crates

• Seaworthy packaging for long-distance shipment

• Global delivery by sea, air, or multimodal transport

• Professional nickel-based alloy manufacturer in China

• Stable raw material sourcing and melting control

• Wide stock and fast production cycle

• Competitive pricing for global projects

• Experience with international EPC, OEM, and distributors

For quotation or technical consultation, please provide:

• Required grade (INCOLOY 825)

• Diameter × Length

• Quantity

• Surface finish / delivery condition

• Application environment

Our technical team will respond with datasheets, pricing, and delivery schedule promptly.