The welding materials market has long been a reliable indicator of activity across manufacturing industries. Recent economic shifts and technological advancements have begun to influence demand patterns for these essential industrial components. This article examines current trends in welding material consumption across major manufacturing sectors without making exaggerated claims or focusing on specific environmental aspects.

Current Market Overview

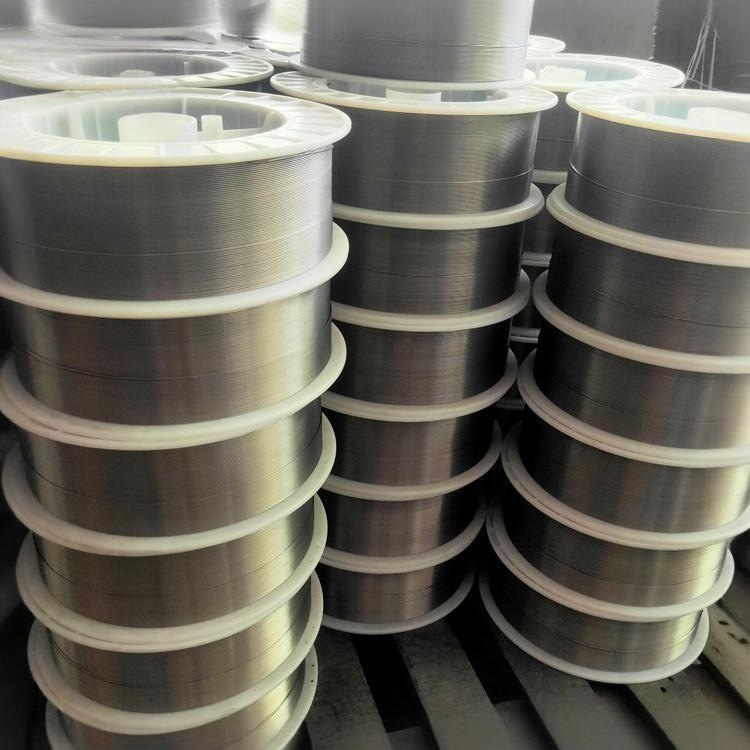

Welding materials remain fundamental to industrial production, with consumption levels reflecting broader manufacturing output. Industry reports indicate moderate growth in the global welding consumables market, though demand patterns show variation between sectors. The market continues to evolve in response to changing production requirements and technological developments in joining processes.

Sector-Specific Demand Changes

Automotive Manufacturing

The automotive industry traditionally represents significant demand for welding materials. Recent developments show:

Moderate reduction in conventional welding material use as vehicle designs evolve

Increased adoption of advanced joining technologies for new vehicle architectures

Stable demand from commercial vehicle production segments

Heavy Equipment and Machinery

This sector maintains consistent welding material requirements with some notable developments:

Sustained consumption levels from construction equipment manufacturers

Growing use of specialized filler metals for equipment durability

Adaptation to newer alloy combinations in heavy machinery components

Energy Sector Applications

Energy-related industries continue to influence welding material demand:

Steady requirements from conventional power generation maintenance

Changing patterns in energy infrastructure projects

Evolving material specifications for high-temperature applications

Technological Influences on Material Demand

Manufacturing advancements are reshaping welding material needs:

Improved welding processes requiring different consumable characteristics

Development of enhanced filler metals with superior performance attributes

Automation trends affecting consumption patterns in high-volume applications

Regional Demand Variations

Geographic factors continue to impact welding material markets:

Established industrial economies maintaining stable baseline demand

Growing manufacturing regions showing increased consumption

Localized shifts in material preferences based on regional industry mixes

Supply Chain Considerations

Recent global events have highlighted several factors:

Improved inventory management practices among manufacturers

Diversification of supply sources for critical welding materials

Continued emphasis on material quality and consistency

Future Outlook

While predicting exact demand levels remains challenging, several trends appear likely:

Gradual evolution of material requirements as manufacturing processes advance

Ongoing adaptation to changing industry needs and specifications

Balanced growth across sectors as industrial production patterns adjust

Conclusion

The demand for welding materials across key manufacturing sectors shows measured changes rather than dramatic shifts. While certain industries are adjusting their consumption patterns, welding remains essential to industrial production. Manufacturers and suppliers continue to adapt to evolving requirements while maintaining focus on quality and performance characteristics that meet industrial needs.